Print The Mold

Mold The Prototype

News & Events

We consistently make headlines in innovation, new product development, and prototyping. Please check here for the latest updates.

Emission norms are rising (BS7/EU7/CAFE III), so are our Quick-turnaround capabilities

Over the years, Magna Digitech has spent extensive engineering effort to support the clean-air shift.

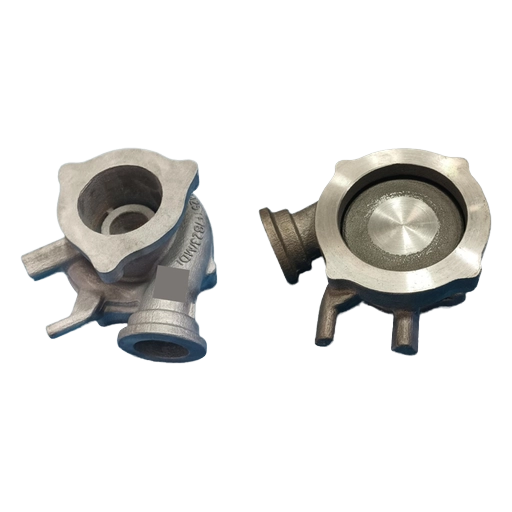

Our Success Story: Rapid Turbocharger components using 3D-Printed Sand Cores

Our Role:

💻 Design Interface + DFM Input

Worked closely with the customer’s R&D team during early design. Exchanged 3D models directly, providing castability feedback on draft angles, feeding paths, and core removal strategies.

These inputs helped avoid late-stage design reworks and accelerated validation.

🖨️ 3D Printed Core Production

In order to accommodate varying volute sizes across different product variants, complex cores were 3D-printed directly from CAD through “Concurrent engineering” practices, eliminating the need for separate core boxes, shell cores or related tooling investments.

This reduced upfront cost and enabled faster iterations.

🏭 Casting & Process Control

Using our simulation softwares such as Magma Soft and Nova Flow, we ensured directional solidification and minimized shrinkage defects. Controlled melt chemistry and pouring practices were aligned with Tier-1 production specifications. NOVA_FILLING.avi

Both Iron and Aluminum housings were poured on our dedicated Furan-based binder lines with imported sand to ensure repeatability.

🔧 Machining

These housings were finished on multi-axis CNCs, with flange flatness and volute profiles held to tight tolerances.

Because volute geometries are especially sensitive in R&D, affecting both thermal durability and efficiency, design changes were frequent. By using a fixtureless, modular machining set-up, we could adapt quickly to each iteration, ensuring test-ready parts without tooling delays.

This gave the customer “Speed to market” while still exploring thermal and flow-critical design changes.

🚚 Rapid Deliveries

The first prototypes were shipped in less than ~ 4 weeks.

Each batch included complete CMM reports and inspection data, providing the customer with full confidence in validation readiness.

The Advantage:

Magna’s flexible, tool-free casting workflows have allowed our customers to validate Turbo components under real-world load cycles months ahead of schedule.

Since then, we have continued to support Tier-1s with rapid deliveries in both Compressor (Al) and Turbine (Fe) housings.

And, today, we are ready to deliver the next wave of Turbocharger components!

Exciting Milestone for Magna Digitech India LLP

We are thrilled to announce the inauguration of our Second Furan Binder Jetting Sand 3D Printer with a job box size of 1200 x 1000 x 650mm! 🎉 This marks a significant leap forward in our 3D printing capabilities, Doubling our capacity for Molds and Cores.

A special thank you to Mr. Jerome Fournier, Prototype Director – France & Mr. Ramanna Paroji, Prototypes – India Operations from Garrett Motion, for gracing the occasion and supporting our journey.

With this new addition, we are committed to enhancing our On-Time Delivery (OTD) and driving Customer Delight with cutting-edge Prototype Solutions.

Stay tuned as we continue to push the boundaries of innovation!

CERAMIC SAND 3D PRINTING

Always striving to Serve you with Newer & Better Technologies

As India’s leading 3D Sand Printing / Proto Casting service

provider, Magna Digitech is proud to announce the availability of

Ceramic Sand Molds and Cores through 3D Printing.

MAGNA DIGITECH is now utilising ‘Ceramic Sand’ for the manufacture of complex Cores and Molds through 3D

Printing.

Ceramic Sand based Molds and Cores offer the following

advantages

- High Sphericity

- Low Thermal Expansion

- High Durability

- High Refractoriness

Allowing us to provide you with Castings having thin complex

Internal passages with superior finish

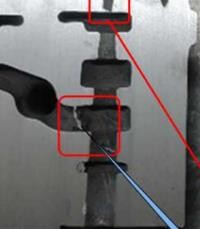

Case study

Root Cause –

Due to the high thermal expansion of Silica Sand, the cores will not withstand the metal temperature, leading to crack of cores resulting in blockage of passages in Hydraulic castings.

Solution – Ceramic Sand cores manufactured by the 3D Sand Printer were able to withstand the temperature of the metal due to its very low thermal expansion and high sphericity, thereby resulting in a

defect free casting. Other benefits were

- Internal Passage dimensions are more accurate

- High Sphericity made it easier for decoring

- Comparatively better surface finish

- Intensity of defects reduced due to its high refractoriness

Thus, switching to Ceramic Sand for High complex parts has been deemed beneficial in many ways. Combining it with Additive Manufacturing makes it much more robust to manufacture parts of high design

complexities like Water Jacket cores, Impellers, Turbine Blades etc. 3D Ceramic Sand Printed Molds and Cores from MAGNA DIGITECH enables manufacture of high-performance complex castings.