Always striving to Serve you with Newer & Better Technologies

As India’s leading 3D Sand Printing / Proto Casting service

provider, Magna Digitech is proud to announce the availability of

Ceramic Sand Molds and Cores through 3D Printing.

MAGNA DIGITECH is now utilising ‘Ceramic Sand’ for the manufacture of complex Cores and Molds through 3D

Printing.

Ceramic Sand based Molds and Cores offer the following

advantages

- High Sphericity

- Low Thermal Expansion

- High Durability

- High Refractoriness

Allowing us to provide you with Castings having thin complex

Internal passages with superior finish

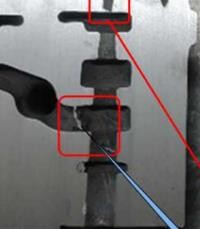

Case study

Root Cause –

Due to the high thermal expansion of Silica Sand, the cores will not withstand the metal temperature, leading to crack of cores resulting in blockage of passages in Hydraulic castings.

Solution – Ceramic Sand cores manufactured by the 3D Sand Printer were able to withstand the temperature of the metal due to its very low thermal expansion and high sphericity, thereby resulting in a

defect free casting. Other benefits were

- Internal Passage dimensions are more accurate

- High Sphericity made it easier for decoring

- Comparatively better surface finish

- Intensity of defects reduced due to its high refractoriness

Thus, switching to Ceramic Sand for High complex parts has been deemed beneficial in many ways. Combining it with Additive Manufacturing makes it much more robust to manufacture parts of high design

complexities like Water Jacket cores, Impellers, Turbine Blades etc. 3D Ceramic Sand Printed Molds and Cores from MAGNA DIGITECH enables manufacture of high-performance complex castings.