Print The Mold

Mold The Prototype

Infrastructure

Our infrastructure seamlessly connects every aspect of concept-to-prototype development, utilising the latest machinery, equipment, and the most advanced CAD/CAM/Simulation software. This integrated approach ensures that our customers benefit from reduced lead times, exceptional quality, and reliable performance.

Our expansive 30,000-square-foot rapid prototyping facility is a testament to our unwavering dedication to your innovation success. It provides a focused environment where your ideas can rapidly materialise with efficiency and impact.

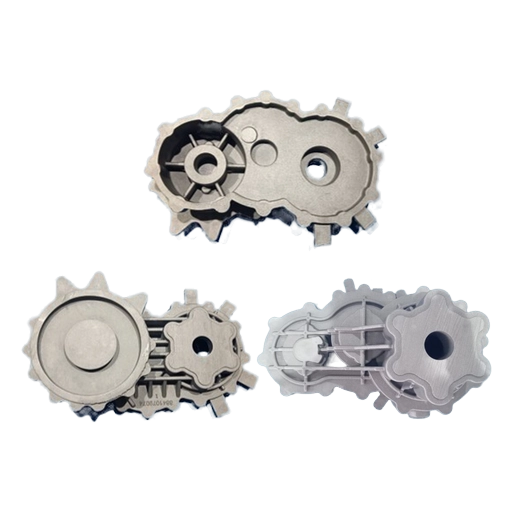

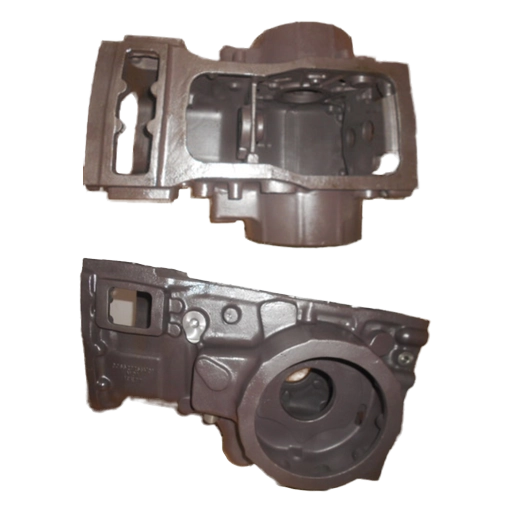

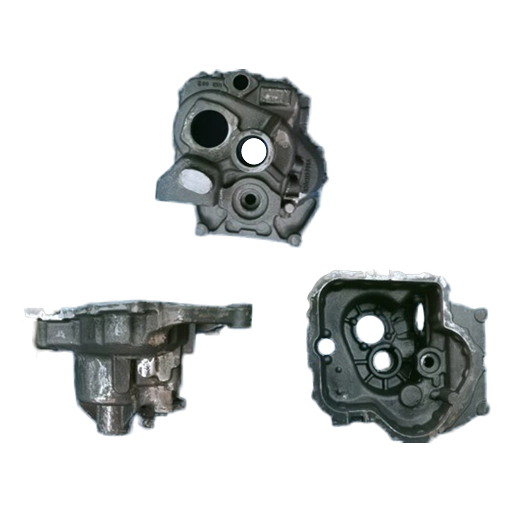

Prototype Development

More than 25 GB of data goes into the design and development of each prototype.

- Each prototype commences with the 3D models

- Backed by simulation expertise in more than 6000 castings

using MAGMA Soft & NOVAFlow&Solid - Machining simulations get executed with precision using

MASTER CAM & EDGE CAM - Additional facilities include CMMs among others

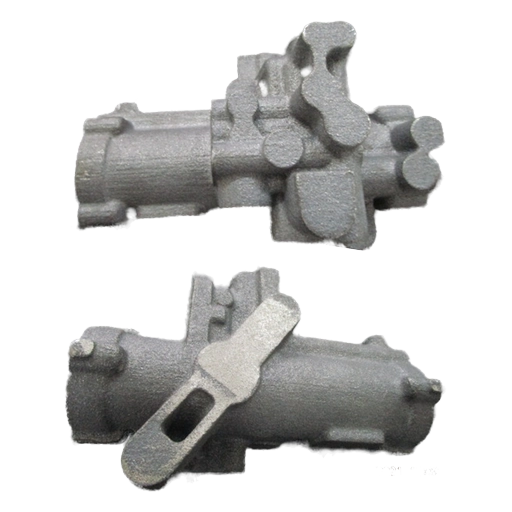

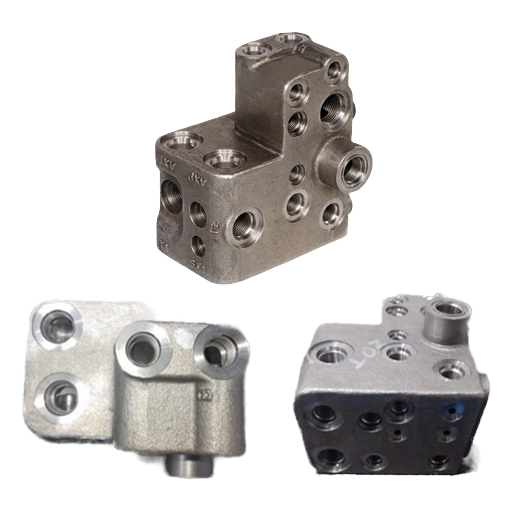

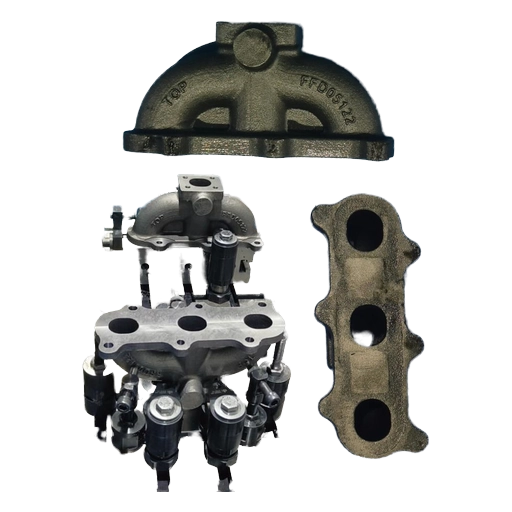

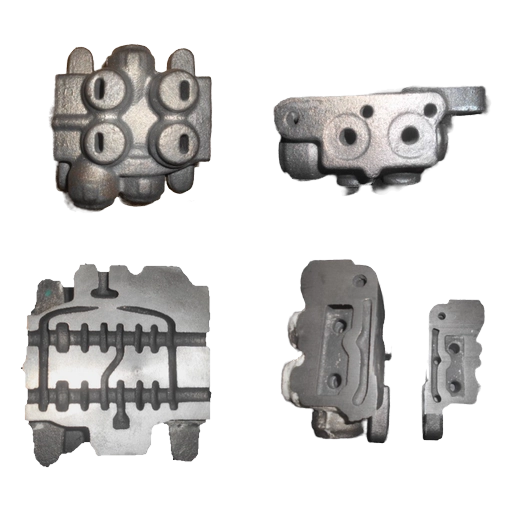

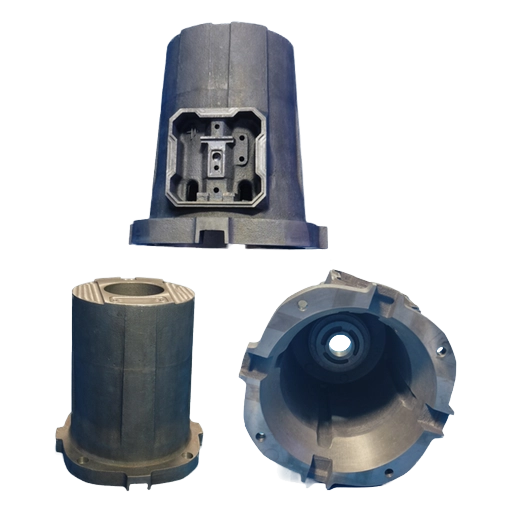

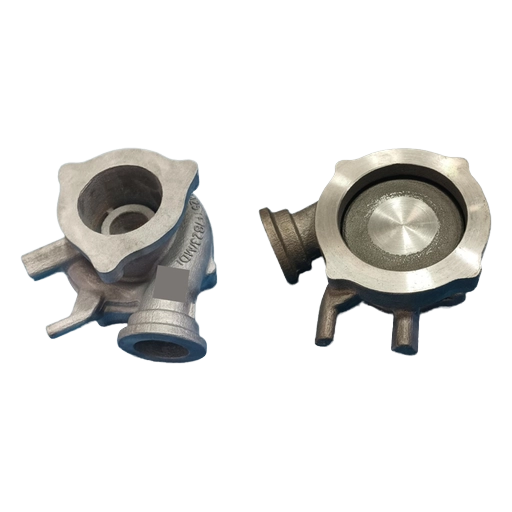

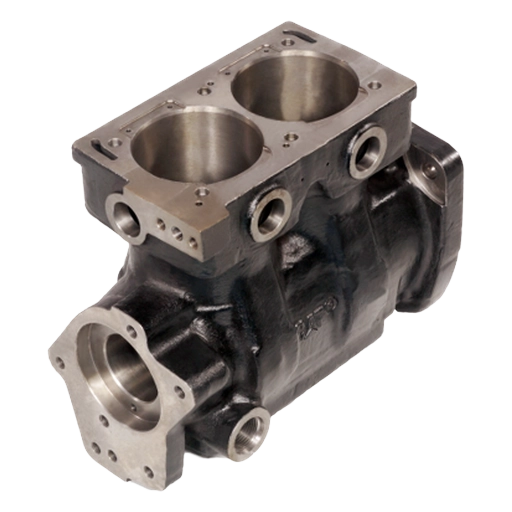

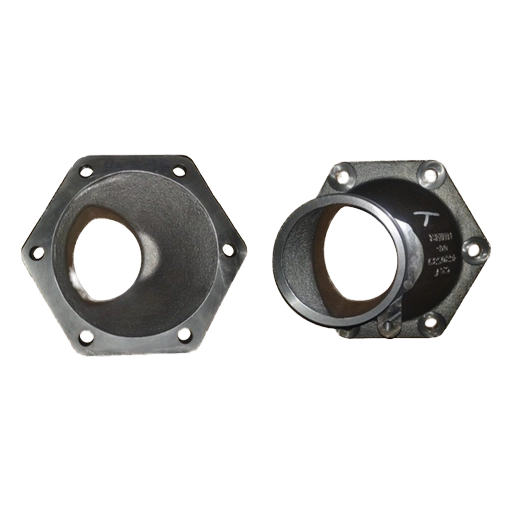

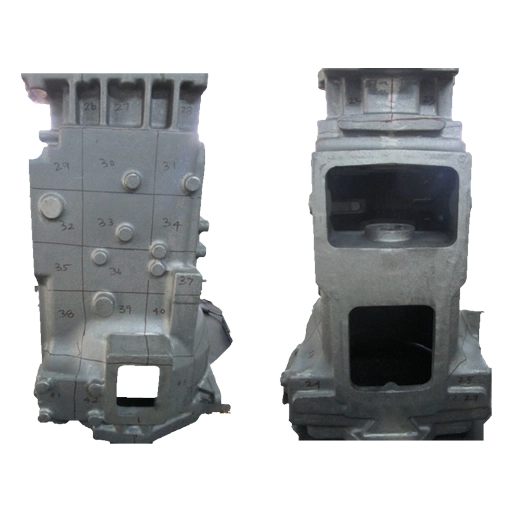

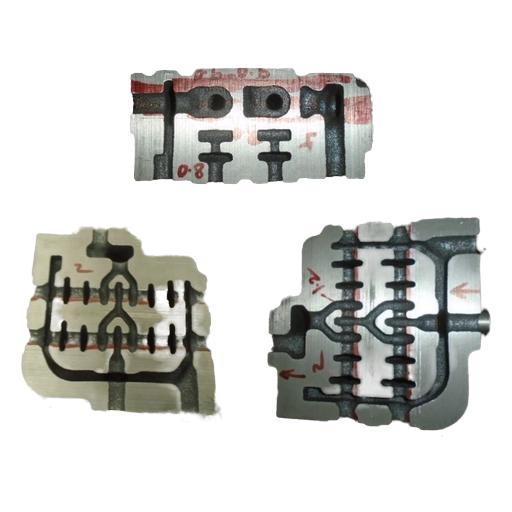

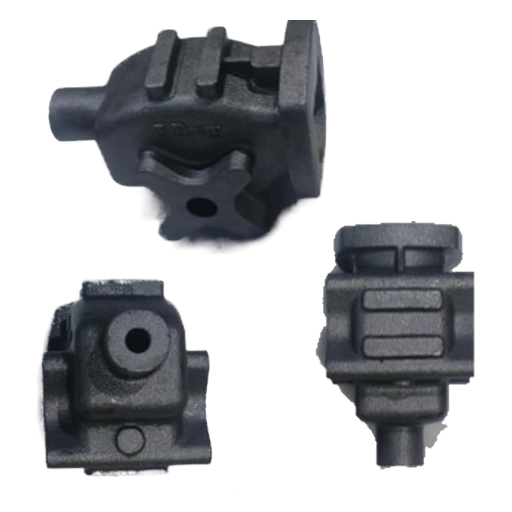

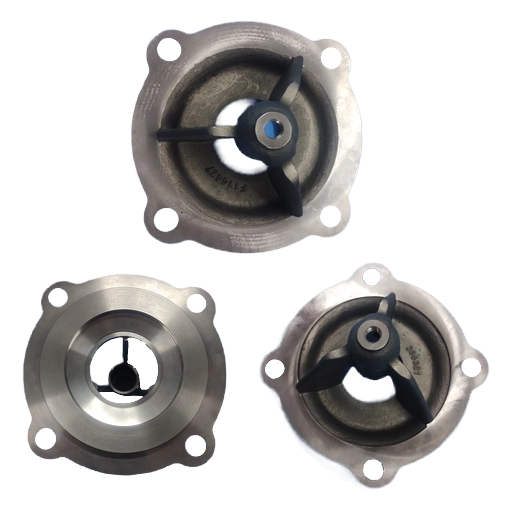

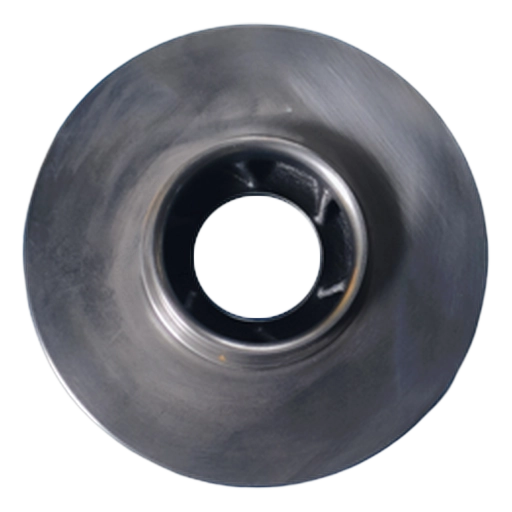

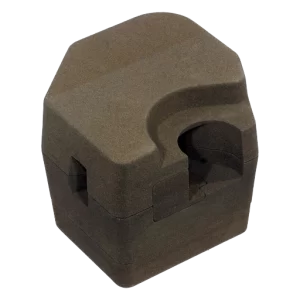

3D Core | Mold printing

We utilise large-format 3D sand printers to create molds and cores for large internal combustion engines, valves, turbochargers, and other components. Smaller molds and cores are nested within the job box according to specific requirements. Our investments in two printers ensure reliable support in case of redundancy.

| No | Machine Type | Process | No of Machines | Capacity | Job Box Size |

|---|---|---|---|---|---|

| 1 | Sand 3D Printer 1 | Furan Binder Jetting Process | 1 | 1100lts | 1500 x 1000 x 750 mm |

| 2 | Sand 3D Printer 2 | Furan Binder Jetting Process | 1 | 720lts | 1200 x 1000 x 600 mm |

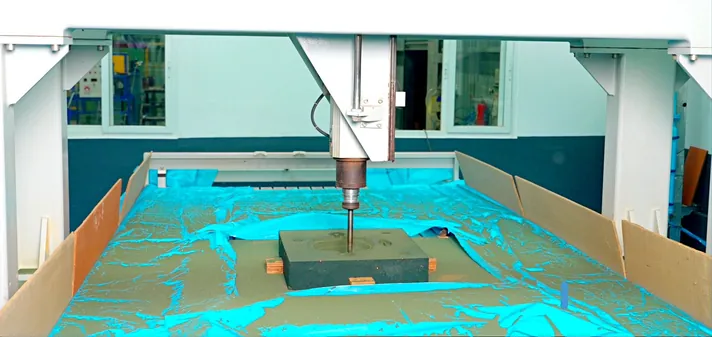

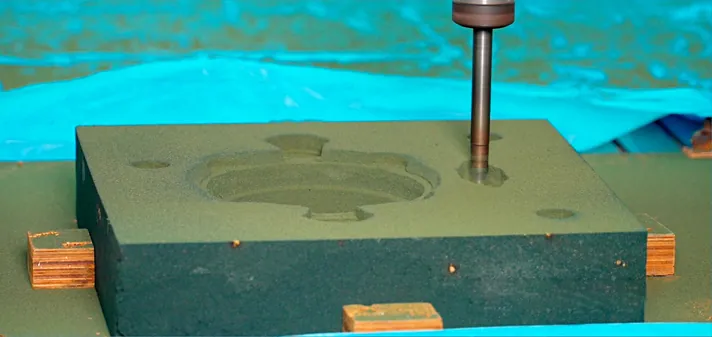

FlexiCAM 3D Router

- Table Size – 2000 mm x 3000 mm

- Accuracy – 25 Micron

Romer Scanner

- Accuracy – 0.045 mm

- Area Coverage – 2.5 meters

- Faster Scanning

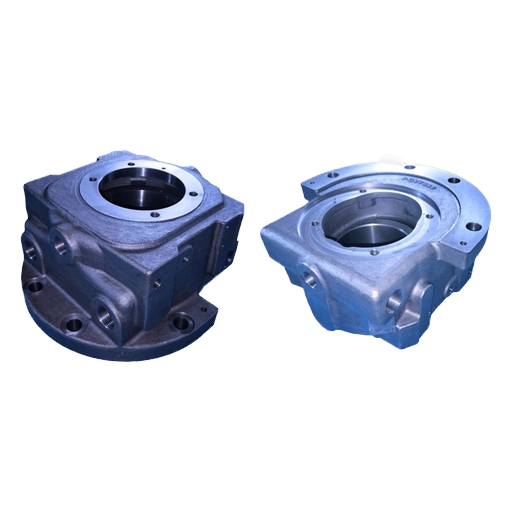

Prototype Machining

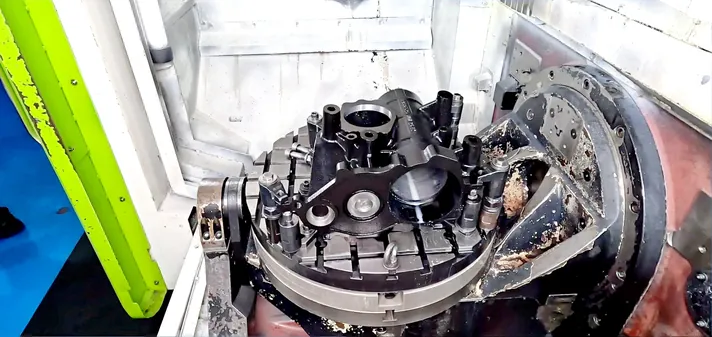

Hartford 5A-65E

- 5Axis Machine

- Table Size – 26”(660 mm) x 20” (500 mm) x 18” (450 mm)

- Diameter – 26” (660 mm)

- Loading capacity – 500 Kgs

| NO. OF MACHINES | TABLE SIZE & MAX. TURNING DIA (MM) | ADDITIONAL FACILITIES | MACHINE ACCURACY | ACCURACY LEVEL |

|---|---|---|---|---|

| 1 | TABLE DIAMETER 650.0 MM | PROBING MODULAR FIXTURE THROUGH COOLANT PRESSURE ENGRAVING CAM PROGRAMMING | XZ - 15 micron YZ - 15 micron XY - 15 micron B axis - 0.001Deg C axis - 0.001Deg | 10 microns |

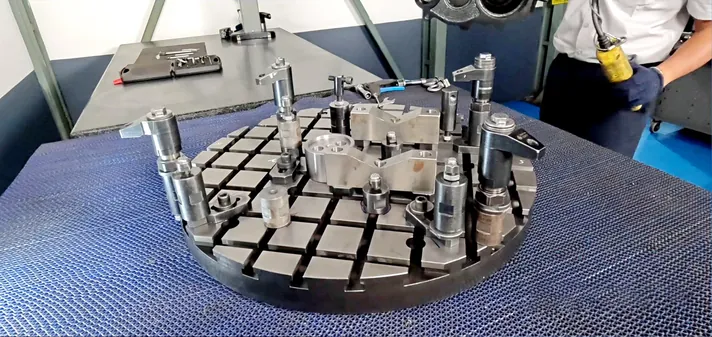

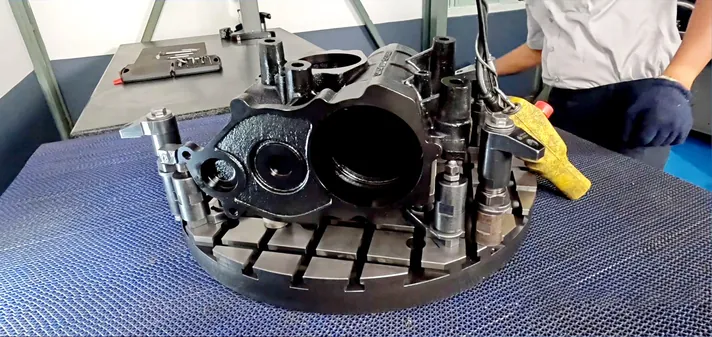

Modular Fixture

- Zero Point Clamping System

- Modular Fixtures can be built in hours whereas a dedicated fixture will take weeks.

- 7 µm accuracy in accessories.

- 5 µm repeatability in Zero Point Clamping system.

- Multiple pallets reduce setup time.

Mazak Integrex J200S

- Horizontal Multi tasking Machine

- Milling Spindle Back Adapter : HSK A63

- Loading capacity – 150 Kgs

- 2-Axis Turning :

– Y Axis Sub Spindle : 8” (200 mm)

– X Axis Main Spindle : 18” (450 mm)

| NO. OF MACHINES | TABLE SIZE & MAX. TURNING DIA (MM) | ADDITIONAL FACILITIES | MACHINE ACCURACY | ACCURACY LEVEL |

|---|---|---|---|---|

| 1 | MAIN SPINDLE CHUCK DIA 250.0 MM, SUB SPINDLE CHUCK DIA 200 MM | PROBING THROUGH COOLANT PRESSURE CAM PROGRAMMING AUTO TRANFERING | XZ - 10 micron YZ - 10 micron XY - 10 micron B axis - 1.0Deg C axis - 0.001Deg | 10 microns |

Mazak VC-Ez 510 IP

- VMC – 4th Axis Machine

- Table Size – 50” x 20”

- Diameter – 3.15”

- Loading capacity – 205 Kgs

- Auto Tool Length Measurement & Break Detection.

- Smooth Synchronized Tapping

- Optical Probe OMP 60 (Renishaw)

| NO. OF MACHINES | TABLE SIZE & MAX. TURNING DIA (MM) | ADDITIONAL FACILITIES | MACHINE ACCURACY | ACCURACY LEVEL |

|---|---|---|---|---|

| 1 | TABLE X ,Y 1250 X 492 | 4TH AXIS PROBING MODULAR FIXTURE THROUGH COOLANT PRESSURE ENGRAVING | XZ - 10 micron YZ - 10 micron XY - 10 micron | 10 microns |

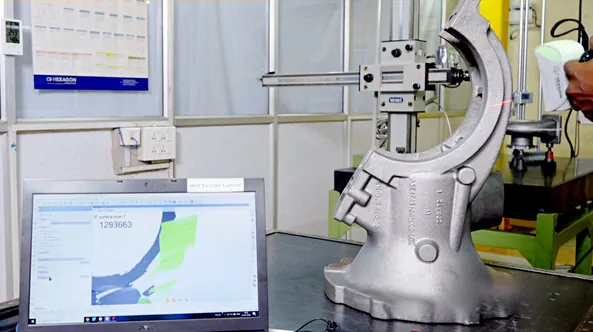

CMM - HEXAGON

- Hexagon Explorer Performance 800 x 1000 x 600 mm with touch trigger scanning and continuous scanning facilities.

- CMM offline programming (PCDMIS)

- Accuracy – 0.1 micron